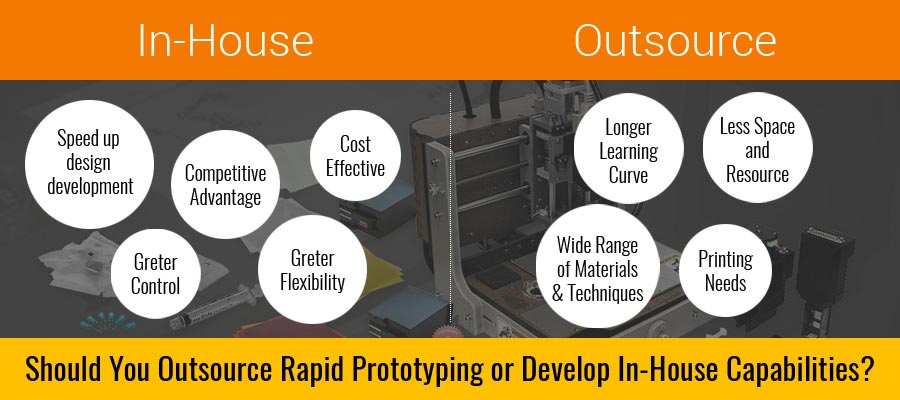

Over the years, product designers and manufacturers have realized the importance of utilizing rapid prototyping in the product development process. This new prototyping technique has allowed engineers to identify flaws early in the design phase and eliminate them before going for a large-scale production. While other prototyping techniques also serve the same purpose, they are not rapid. 3D printing however, helps companies to develop prototypes faster directly from the CAD model. Moreover, the increasing availability and affordability of 3D printers, makes it an ideal choice for companies and enables them to develop prototypes in-house. However, there is an increase in number of outsourcing firms as well who provide rapid prototyping services to manufacturers, which further helps companies to reduce cost of prototyping and gain advantage of working with experienced professionals in the industry. Let’s look at the benefits of each of these approaches, i.e. in-house Vs outsourcing.

Investing for in-house 3D printer

Considering the development of in-house rapid prototyping capabilities can yield numerous benefits; here are some of the important ones:

Speed up design development

In-house 3D printing capabilities will ensure that the time required in product development process can be reduced considerably and products can brought to market faster. Since you will have your own 3D printer, you can easily develop prototypes, determine design flaws and re-design the part/product rather than handing over the task to outsourcing firms and who will take their own time in prototype development.

Increase in competitive advantage

With in-house 3D printer, you can perform prototyping frequently, which means more iterations can be performed easily. This will enable you to develop better products, as you will not have to settle for a less ideal design to reduce the complexities of redesigning. Rather, you can perform number of experiments quickly until an ideal design is achieved.

Greater control on development process

Since you will have direct control on production, it becomes easier to eliminate errors early and gain a better control on the entire development process, which can ensure innovative development.

Greater design flexibility

With rapid prototyping, companies can test and modify designs quickly. This possibility has enabled manufacturers globally to develop new designs, which although are incomplete at the beginning, but are far more refined at the end, due to the flexibility design engineers have.

Cost effectiveness

With in-house 3D printers, the cost of product development can be reduced significantly in the long run. Despite high initial investment, it is possible to develop low-volume prototypes as well as production-ready parts through advanced 3D printers that can replace your existing production processes.

Secure intellectual property

Since prototype development is carried out in-house, you can safeguard critical design data and ensure the security of your product designs rather than handing over to some third-party service providers.

The Outsourcing Equation

Despite numerous benefits of keeping an in-house 3D printer, outsourcing too is a valuable alternative for many manufacturers looking for implementing rapid prototyping for their product development. Let’s look at these in detail:

Printing needs

In most cases, companies do not require the need for continuous printing support. For most of them, 3D printing is not a part of their business model and investing for in-house 3D printer can be of no benefit to the company. If the printing requirement is infrequent, outsourcing is a cost-effective way.

Longer learning curve

While 3D printing is an exciting technology, it is still a little complex to learn operating these printers properly to avoid wastage and get the prototype as expected. Many companies focused on implementing other trainings can find it difficult to allocate resources for gaining expertise with 3D printing. In such cases, it is a good option to outsource projects to experienced and trained professionals who know how to efficiently operate 3D printers.

Less space and resource availability

There may be instances when companies have lack of space in their premises to accommodate an industrial 3D printer. Or they might not have enough budget and required resources to manage rapid prototyping activities. Partnering with a 3D printing service provider can be more efficient in these scenarios rather than investing in people and space.

Wide range of materials and printing techniques

Prototype requirements vary at different stages of the development process and hence it is not possible to invest in different material printing capabilities. Outsourcing firms providing rapid prototyping services usually have a wide range of 3D printing capabilities with different materials to choose from. This is due to the fact that their core business model is rapid prototyping.

Irrespective of whether you outsource 3D printing or consider investing in the technology to improve in-house capabilities, rapid prototyping is here to stay for a long time. Its use is significant in aerospace and automotive industries and is gradually making its way to replace conventional manufacturing techniques like machining and injection molding. With greater design flexibility and the ability to shorten the product development time, 3D printing should be a part of every manufacturer’s product development strategy.